GHG Reduction Activities

Transition of Corporate Vehicles to Eco-friendly Vehicles

To reduce greenhouse gas emissions, MCNEX is transitioning its corporate vehicle fleet to eco-friendly vehicles. Since 2023, the company has been replacing its existing gasoline and diesel vehicles with hybrid vehicles and electric vehicles (EVs) certified as Type 1 or Type 2 low-emission vehicles (a Korean standard). Concurrently, MCNEX has installed 4 EV charging stations in its company parking lots, establishing EV infrastructure to make it easier for employees to commute with eco-friendly vehicles. In 2024, MCNEX purchased an additional two eco-friendly vehicles, bringing the proportion of eco-friendly vehicles in its currently operational corporate fleet to 18%.

Third-Party Verification of Greenhouse Gas Emissions

To achieve its 2050 Net Zero target, MCNEX is striving to manage greenhouse gas emissions from its business sites. To provide reliable information to stakeholders and transparently disclose ESG information, MCNEX completed third-party verification of its greenhouse gas emissions in April 2025. This verification covered the three years 2019, 2023, and 2024, with the organizational boundary defined as its Incheon headquarters and MCNEX VINA, and it assessed the company's direct (Scope 1) and indirect (Scope 2) greenhouse gas emissions. Subsequently, MCNEX obtained verification for this data from Intertek, a global certification body.

Energy Use Reduction Activities

Reducing Energy Use at Business Sites

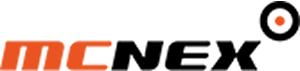

MCNEX conducts energy-saving campaigns and encourages all employee participation to reduce energy consumption and greenhouse gas emissions. Additionally, for effective electricity consumption reduction, the company is operating 42 virtual machine (VM) servers on 6 physical servers through virtualization. MCNEX expects this to reduce its electricity consumption by approximately 85% and plans to continue investing in energy reduction activities.

MCNEX VINA is undertaking various activities to reduce its energy consumption. Through initiatives such as replacing fluorescent lights and streetlights on its premises with LEDs and installing inverters on the controllers of water supply pumps for water tanks, MCNEX VINA has achieved an annual electricity reduction of 54,960 kWh.

Power Resource Optimization through Server Virtualization

Introduction and Expansion of Renewable Energy

Approximately 98% of MCNEX's total greenhouse gas emissions come from its electricity consumption. To reduce carbon emissions and energy costs, MCNEX installed solar panels in unused spaces, such as the rooftop and rest areas of MCNEX Tower, in December 2024; these panels are now operational. They are expected to generate 105 MWh of electricity annually, leading to an anticipated average emissions reduction of 50 tCO₂eq per year. MCNEX VINA also plans to install solar panels on all facilities at its Plants 1, 2, and 3.

Classification | Unit | 2025 | ||||

Jan | Feb | Mar | Apr | May | ||

Renewable energy usage | kwh | 4,170 | 8,540 | 11,291 | 12,087 | 11,311 |

Water Resource Management

Water Usage and Wastewater Management

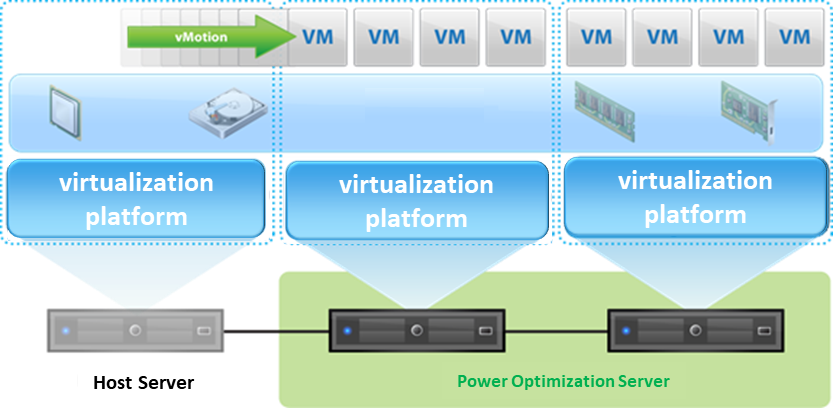

At MCNEX's Songdo headquarters, wastewater is not generated during the development and development sample processing stages. However, at MCNEX VINA, wastewater is generated during its manufacturing processes. To recycle this, a water regeneration system has been introduced and is currently operational. In 2024, the volume of recycled water was 212,219 tons, achieving a recycling rate of 58%.

Additionally, MCNEX VINA conducts quarterly tests of its discharged wastewater quality, striving to ensure emissions remain below legal concentration standards. In particular, to enhance the monitoring of water usage and effluent in 2025, MCNEX VINA established a wastewater discharge monitoring system this year. The monitoring system inspects wastewater discharge quality and allows for real-time checking of discharge volumes. In addition, MCNEX strives to conserve water through company-wide water-saving campaigns.

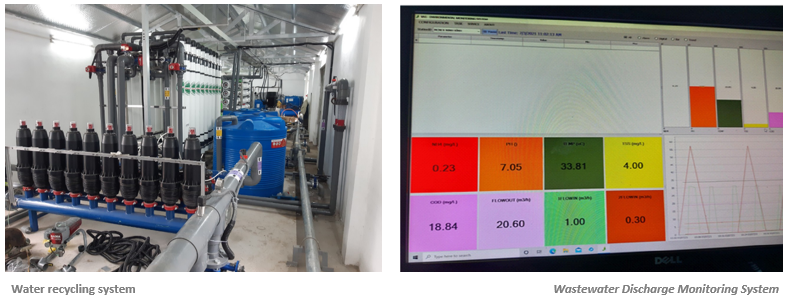

Water Resource Risk Management

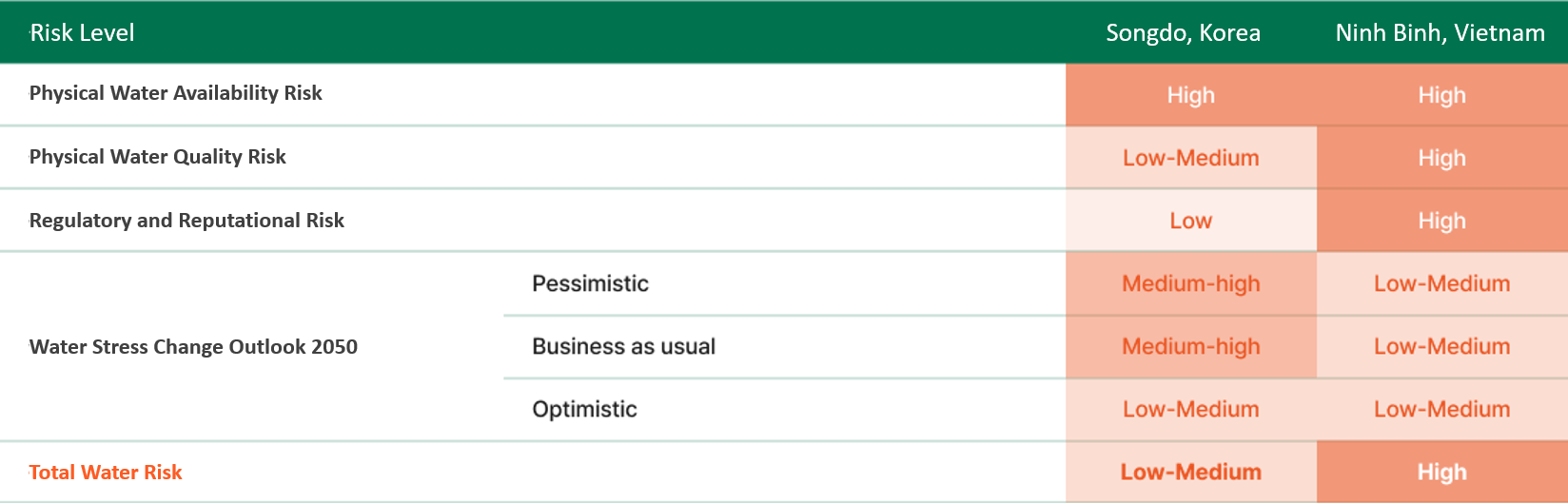

MCNEX utilizes the WRI Aqueduct Water Risk Atlas to identify and systematically manage key water-related risk factors. A recent analysis conducted for its Incheon headquarters and the Vietnam Ninh Binh plant confirmed that the Vietnam Ninh Binh plant is located in a region with high water resource risk. Given that the Vietnam Ninh Binh plant is a major site responsible for producing key products, MCNEX plans to prioritize managing its water resource risks to ensure the continuation of stable operations. In 2024, MCNEX achieved the ‘Awareness’ Level in the CDP Water Security assessment.

Waste Management

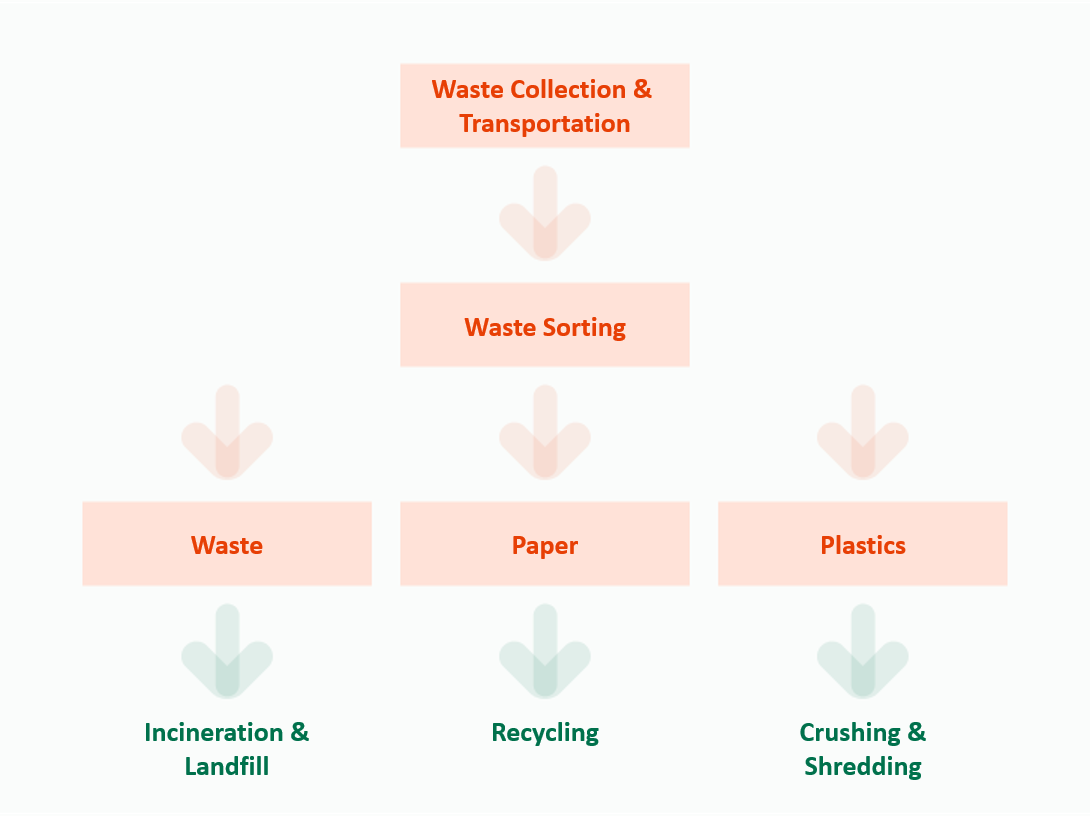

MCNEX accurately records and manages the waste it generates in accordance with the domestic Waste Management Act and Ministry of Environment guidelines. General waste is incinerated through designated waste treatment companies, while designated waste (primarily generated from cleaning solutions used in product washing) is consigned to specialized waste treatment companies for disposal.

MCNEX stores designated waste generated from its business activities in specified storage areas and manages it on a regular basis. Subsequently, this designated waste is collected and treated by the consigned companies, and MCNEX registers and discloses related performance data through the Allbaro System.

Waste Treatment Process

Hazardous Chemical Management

MCNEX complies with global standards for hazardous substances in products, such as EU RoHS, REACH, and IMDS. In 2023, the company submitted its chemical emissions report to Korea's Chemicals Safety Agency and continuously manages its chemical emissions to ensure they remain below 10 tons. For chemicals used in its laboratories, MCNEX prepares Material Safety Data Sheets (MSDS) and makes them readily accessible within the labs for all personnel.

MCNEX MSDS

Air Quality Management

MCNEX VINA regularly measures the volume of pollutants emitted from its air pollution-emitting facilities and manages these emissions in compliance with legal standards.

Product Environmental Impact Management

Raw Material Management

MCNEX promotes sustainable resource use by efficiently utilizing raw materials in its production processes. As a result of continuous R&D investment, MCNEX unveiled an ultra-slim, high-resolution camera module at CES 2025 in January 2025. This module, featuring a slim-type actuator and packaging, significantly reduces thickness compared to existing products and is expected to contribute to smartphone lightweighting and a reduction in raw material consumption. Furthermore, MCNEX designs its products with modularity for easy disassembly, remanufacturing, and recycling, and strives during the design phase to use homogenous materials to facilitate these processes.

CES 2025

Promoting a Circular Economy

To promote a circular economy, MCNEX applies recycling marks to products from its ‘Eyeclon’ brand, under which it has launched items such as black boxes (dash cams) and golf rangefinders. Furthermore, for the collection, recycling, and recovery of waste electrical and electronic equipment (WEEE), the company also affixes the WEEE certification mark. Additionally, MCNEX arranges for external organizations to conduct analyses and evaluations of hazardous substances that may be generated from WEEE, thereby proactively preventing related risks.

Recycling · WEEE Marks

Life Cycle Assessment (LCA)

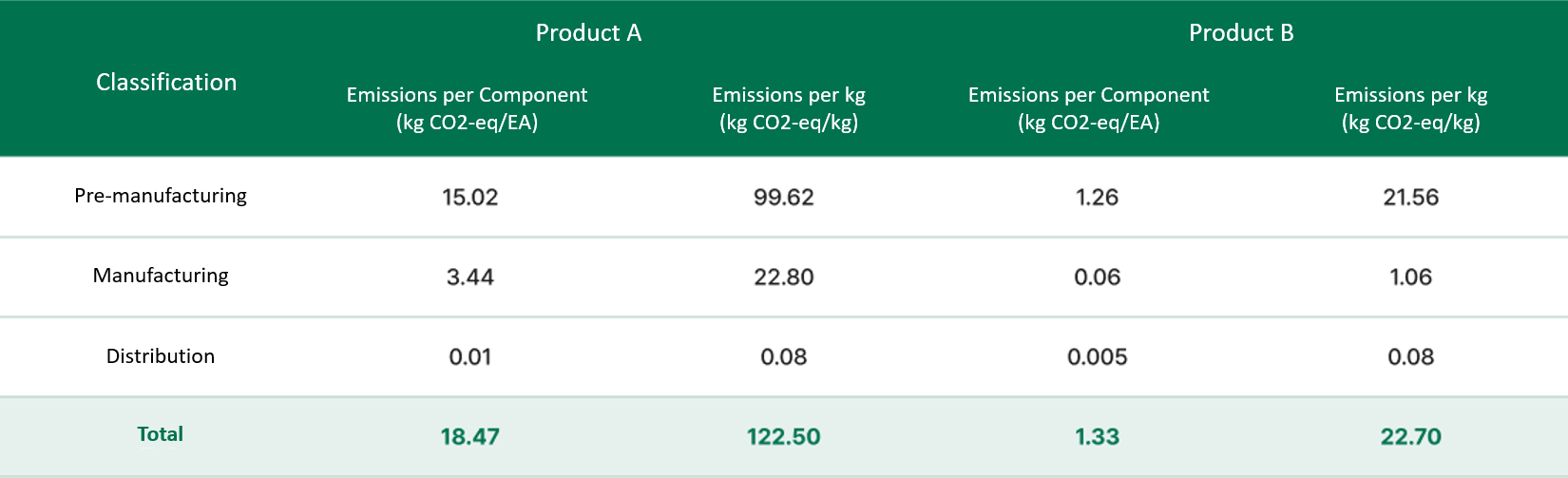

MCNEX conducts analyses of carbon emissions generated during the pre-manufacturing and manufacturing stages of its products and strives to reduce greenhouse gases generated during its product manufacturing processes. In 2024, MCNEX conducted an LCA for two camera module products that were in production. The assessment involved collecting data from the pre-manufacturing stage (raw material production) up to the transportation, product manufacturing, and distribution processes. It utilized a combination of direct and indirect investigation methods, depending on the supply chain management level for each component. The assessment results found that the two camera module products emitted 1.33 kgCO₂-eq and 18.47 kgCO₂-eq, respectively.

Life Cycle Assessment

Emission Ratio by Stage