Sustainable Supply Chain

Supplier Code of Conduct

To establish a sustainable supply chain, MCNEX enacted its Supplier Code of Conduct in May 2024. This Code of Conduct outlines principles that suppliers must adhere to in their business operations concerning overall sustainability, including areas such as human rights, safety and health, the environment, and ethics. In 2024, MCNEX received signed commitments to comply with this Code of Conduct from a total of 42 suppliers.

Supplier Selection and Management

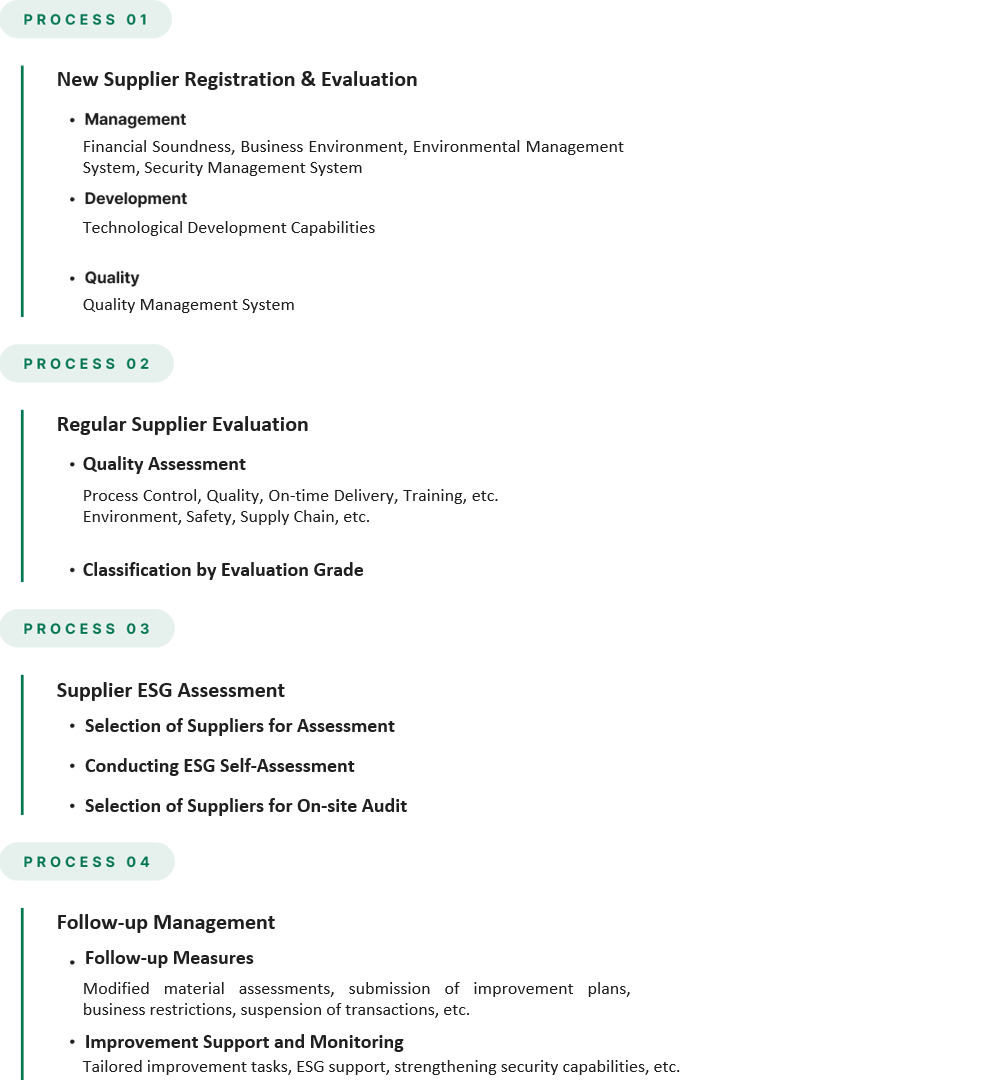

MCNEX selects and registers new suppliers by conducting comprehensive assessments in Management, Development, and Quality. This comprehensive assessment for new suppliers goes beyond mere product supply capabilities; it holistically reviews business and ESG aspects—such as managerial stability, environmental regulatory compliance, cybersecurity response systems, and potential for technological innovation—to evaluate the potential for mutual growth with MCNEX.

Registered suppliers undergo systematic annual evaluations on key items including quality levels, on-time delivery rates, environmental and safety management activities, and compliance with ethical management. Suppliers are graded A to C based on evaluation results. Follow-up measures are applied by grade—such as modified material assessments, requests for improvement plan submissions, business restrictions, or suspension of transactions—to encourage their continuous self-improvement of capabilities. In particular, for suppliers with unsatisfactory results, MCNEX assigns tailored improvement tasks along with a cause analysis, and, where necessary, offers support to enhance their quality, ESG management, and security response capabilities. Furthermore, for suppliers identified with high cybersecurity risks, MCNEX mandates separate cybersecurity interface reviews and the establishment of response plans. The company also strengthens the overall digital security framework by regularly inspecting their management levels.

Through this virtuous cycle of supplier management, MCNEX continuously enhances the quality and sustainability levels across its entire supply chain. The company actively promotes responsible purchasing activities to achieve win-win cooperation with suppliers and realize ESG values.

New Supplier Selection and Registration Process

Supplier Quality Management Process

MCNEX evaluates the quality grade of its suppliers monthly by consolidating the results of incoming inspections. Evaluation criteria include defect rates, the effectiveness of corrective actions, and occurrences of process and finished product quality issues. Suppliers are then classified into grades A to C based on their overall scores. For C-grade suppliers, MCNEX mandates the presentation of improvement measures and verification of their effectiveness. The company promotes quality improvement for both domestic and international suppliers through video conferences and on-site inspections. All evaluations are conducted by qualified quality assessors, and the results are shared with the purchasing team for consideration during supply contract renewals. All evaluation-related records are managed transparently and retained for a minimum of three years.

Supply Chain ESG Risk Management

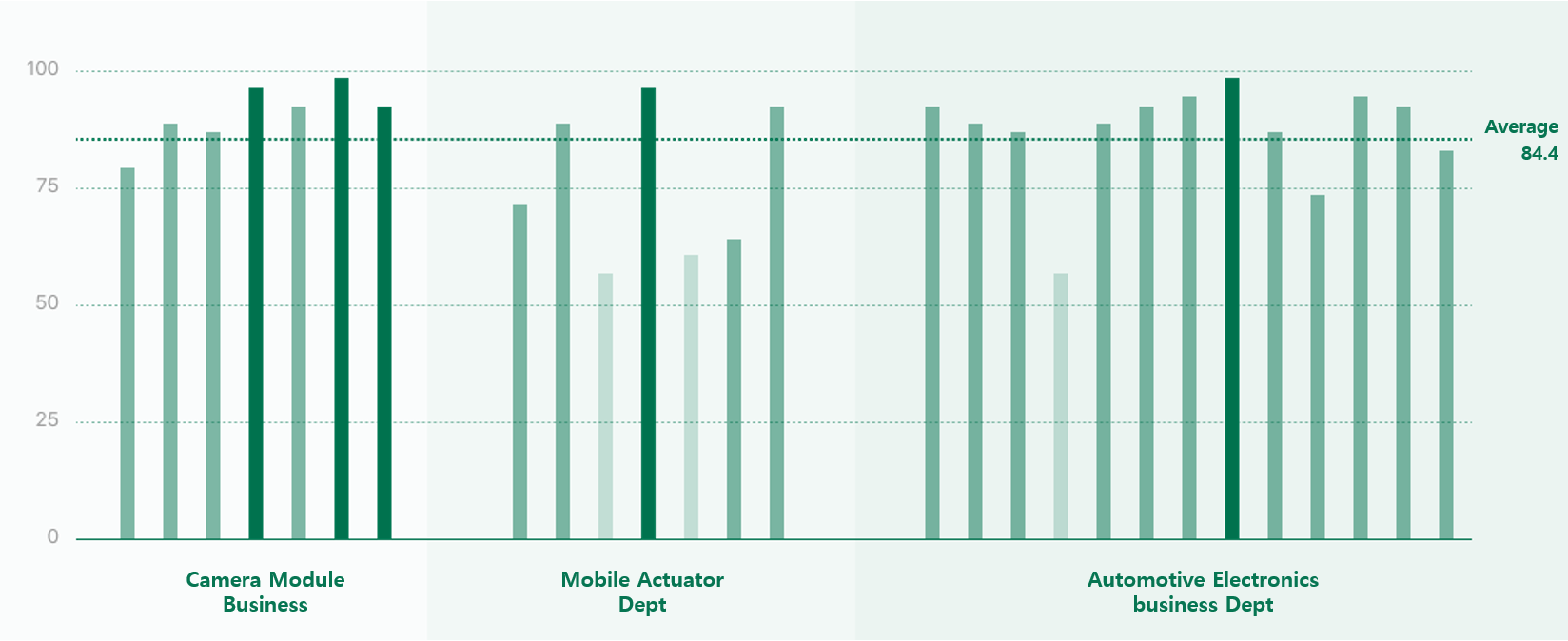

To enhance sustainability across its entire value chain, MCNEX assesses ESG risks for its key suppliers. This supply chain ESG risk assessment is conducted annually using a comprehensive checklist that considers ESG factors such as quality management, human resource development, supply chain management, and environmental aspects.

Based on the assessment results, suppliers who fail to meet the evaluation criteria (i.e., receive a grade of D or below) are designated as requiring focused management. They are requested to implement corrective actions, undergo secondary audits, and make other necessary improvements. In 2024, to strengthen its supply chain ESG management capabilities, MCNEX updated its existing ESG risk assessment to include 51 detailed items reflecting requirements from global initiatives in areas like environment, human rights, information security, and ethics. This updated assessment was conducted for 27 suppliers, and MCNEX also collected Supplier Code of Conduct compliance pledges from 42 suppliers. Additionally, MCNEX plans to enhance its supplier selection and management process to incorporate ESG factors when selecting new suppliers. In 2025, the company aims to achieve a sustainable supply chain by expanding the ESG risk assessment items and conducting these more broadly.

Supplier ESG Self-Assessment Results

Responsible Resource Sourcing

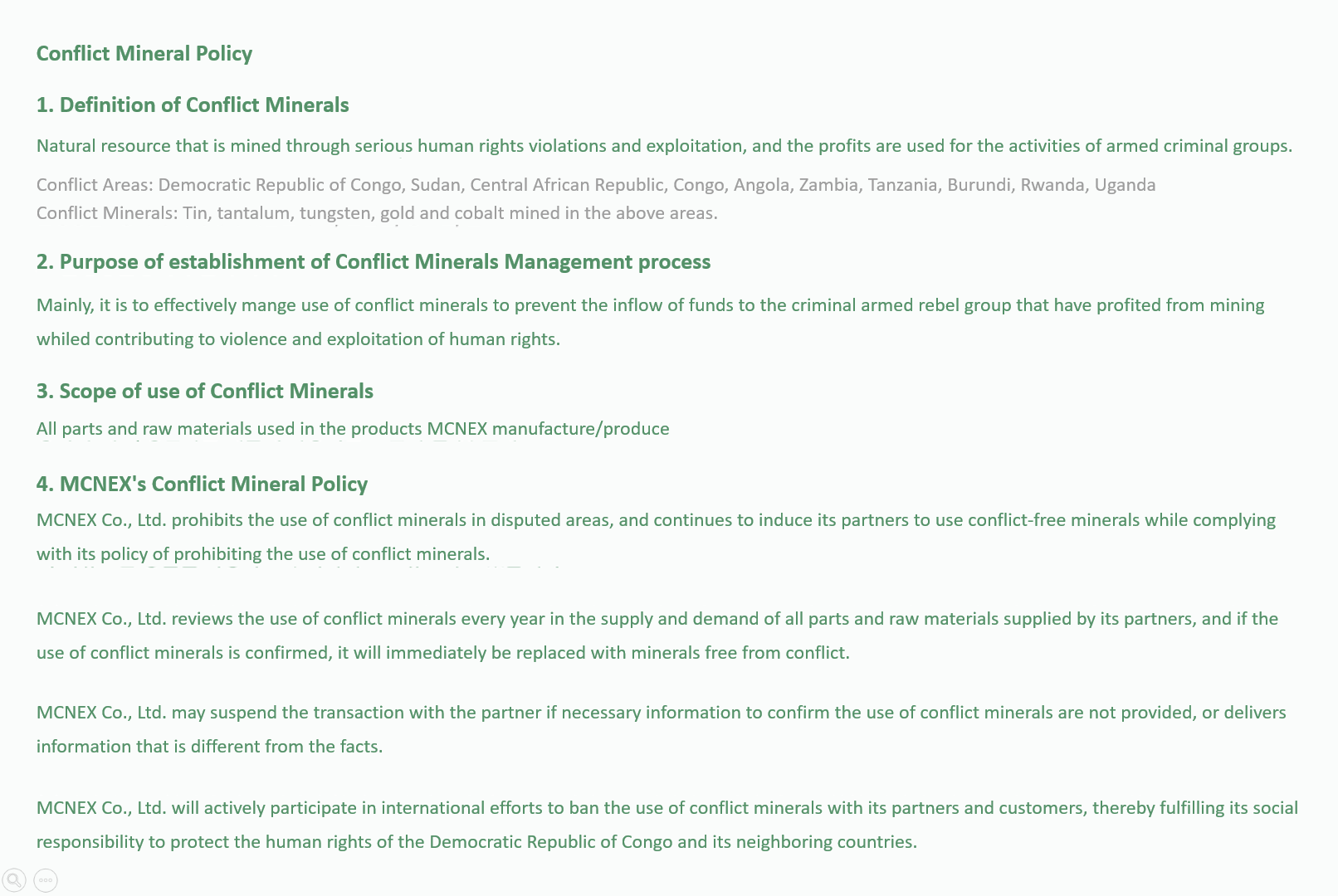

Conflict Minerals Policy

Conflict minerals are defined as minerals such as tin, tantalum, tungsten, and gold (3TG), produced in conflict-affected countries including the Republic of the Congo, the Democratic Republic of Congo (DRC), Sudan, and the Central African Republic, among others. As the production of these minerals raises concerns about funding armed groups and human rights violations, MCNEX prohibits the use of conflict minerals sourced from such regions.

MCNEX annually reviews all parts and raw materials procured for its products to determine if conflict minerals are used. If their use is identified, they are immediately replaced with conflict-free alternatives. MCNEX also encourages its suppliers of parts and raw materials to comply with this conflict minerals policy. If a supplier fails to provide necessary information for verifying the use of conflict minerals, or if it is confirmed that false information has been provided, MCNEX suspends business with that supplier.

Going forward, MCNEX, in collaboration with its suppliers and customers, will actively participate in international efforts to prohibit the use of conflict minerals and will fulfill its social responsibility to protect human rights in the Democratic Republic of Congo and adjoining countries.

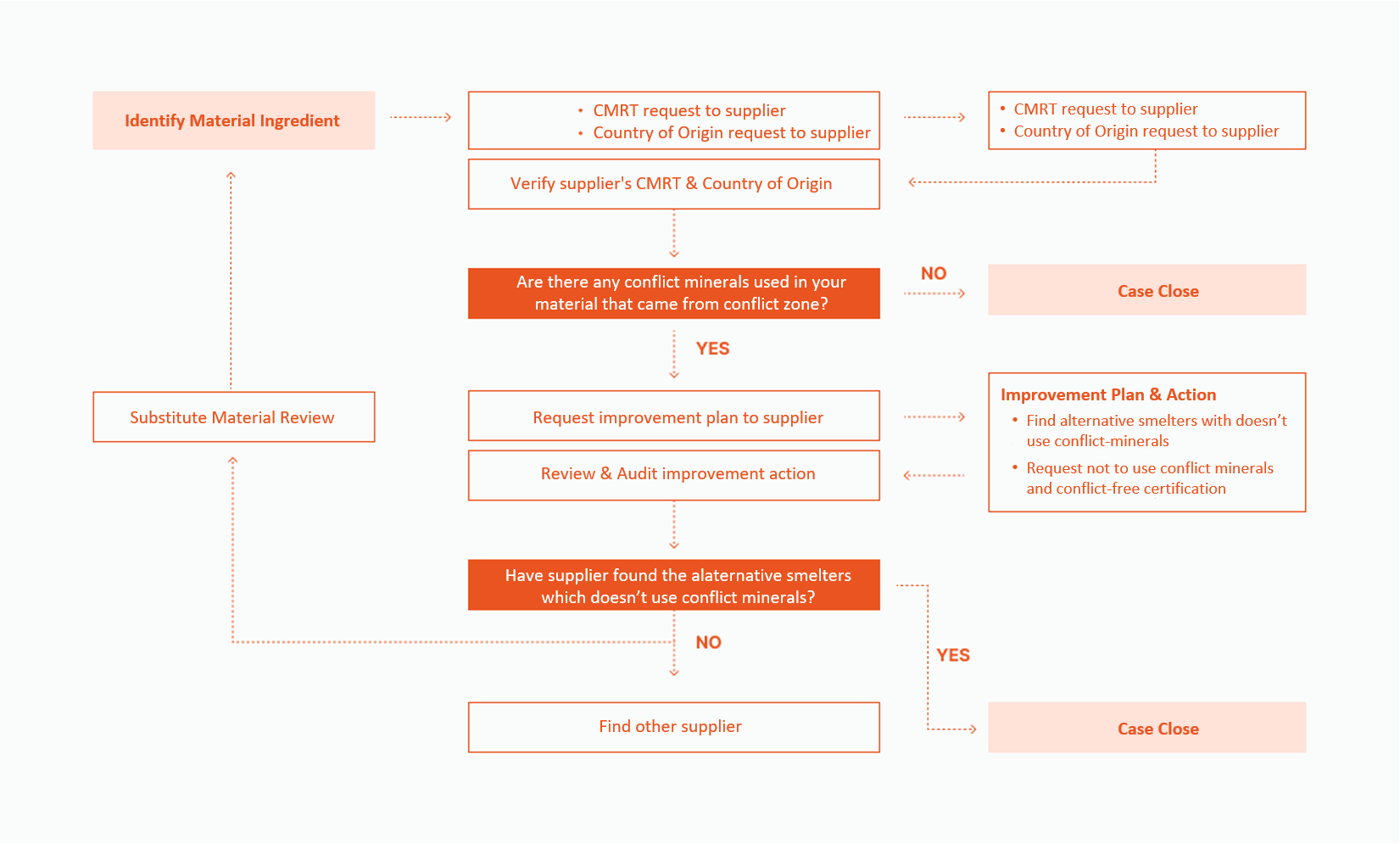

Conflict Minerals Management Process

MCNEX recognizes the severity of serious human rights abuses associated with minerals mined in conflict regions and fully supports the vision, mission, and goals of the RMI (Responsible Minerals Initiative) concerning conflict minerals.

In accordance with the due diligence process recommended by the RMI, MCNEX implements traceability management for conflict minerals and responsible minerals using CMRT (Conflict Minerals Reporting Template) and EMRT (Extended Minerals Reporting Template). For the risk analysis of conflict and responsible minerals, MCNEX utilizes its internal ERP system to compile lists of materials and parts required for product production, and then identifies items containing these minerals. The risk analysis identified that MCNEX sources such minerals from two suppliers. Upon receiving their CMRT/EMRTs, it was confirmed that both suppliers use smelters conformant with responsible sourcing programs. Furthermore, to prevent risks associated with conflict and responsible minerals, MCNEX has established a Conflict Minerals Task Force (TF), comprising representatives from relevant departments including Purchasing, R&D, and Contracts, to carry out related duties.

Conflict Minerals Management Process

Organization | Details | Management Documents |

Purchasing Team | - Leading company-wide conflict minerals compliance | ▶ CMRT/EMRT |

R&D Team | Domestic New Purchases | ▶ KQIS Registered Data (CMRT/EMRT) |

Contracts Team | Outsourced Suppliers | ▶ Contract Clause Management |

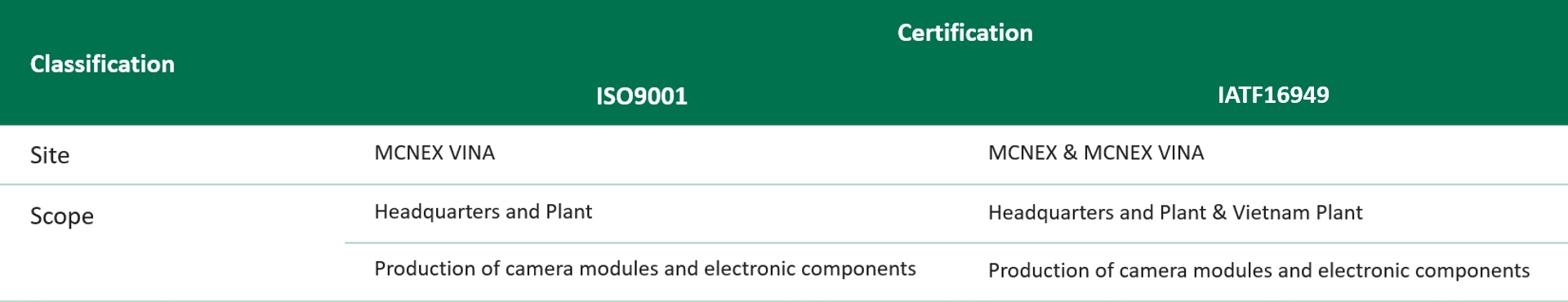

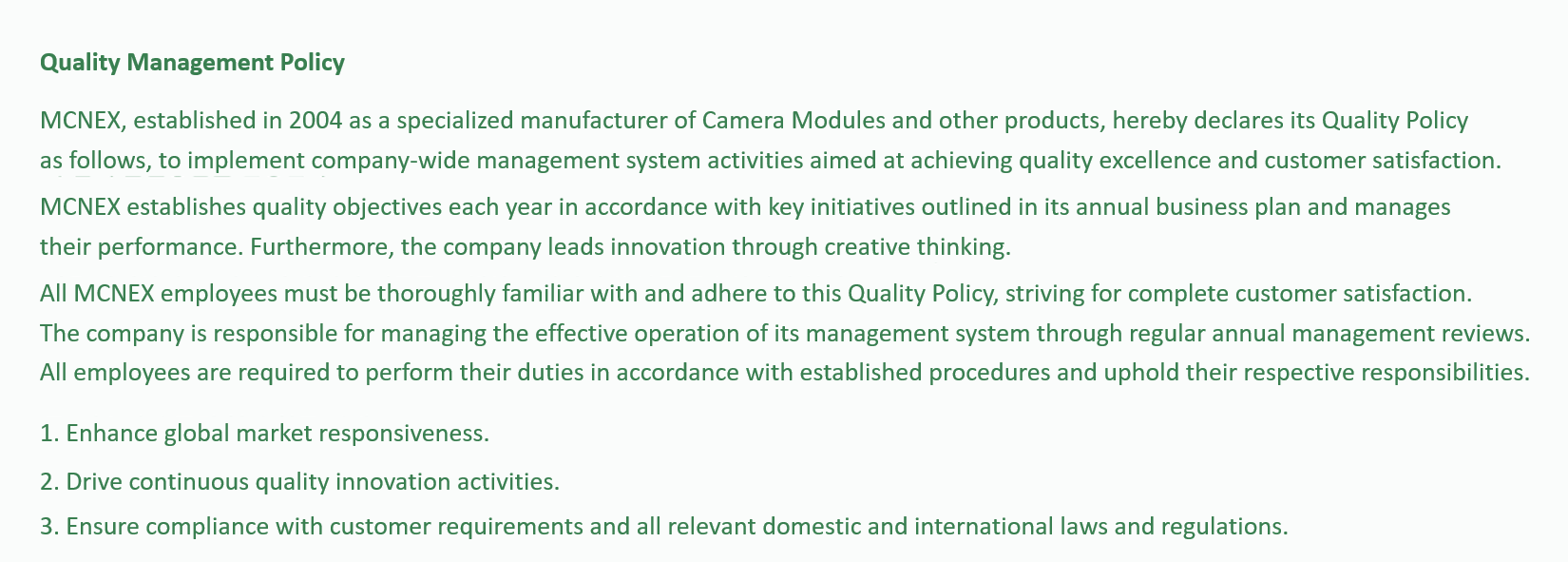

Quality Management

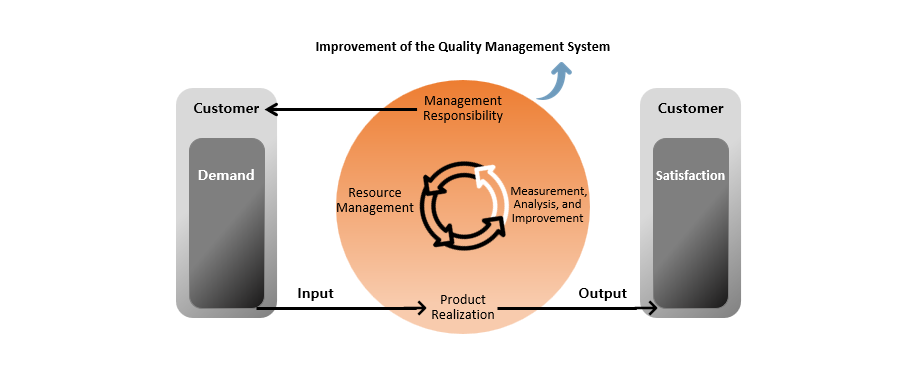

Quality Management System

MCNEX prioritizes customer value and operates a systematic production quality management system to secure its unique competitiveness. Following the PDCA (Plan-Do-Check-Act) methodology, MCNEX annually establishes quality objectives for key initiatives and manages them intensively. Furthermore, for its increasingly diversified global network, MCNEX provides diverse sales and technical support services. While complying with the laws and regulations of each respective country, the company builds mutual trust and cooperative relationships to achieve customer satisfaction.

Quality Training

To enhance company-wide quality competitiveness, MCNEX provides job-specific training for employees in quality-related departments. This quality training, aimed at strengthening job competency and professional expertise, consists of sessions led by invited external expert instructors as well as online courses. In 2024, a total of 500 hours of job-specific quality training was provided.

Customer Satisfaction Management

MCNEX employees adhere to the Quality Policy and the ‘1:10:100 RULE’ in their work to achieve Zero Quality Defects. The 1:10:100 RULE is MCNEX's core quality principle: 'If a problem is not resolved at the development stage at a cost of "1," production costs will increase tenfold to "10," and if field defects occur, failure costs will escalate a hundredfold to "100."' In line with this principle, MCNEX identifies issues within the categories of prevention costs, appraisal/correction costs, and failure costs, and develops improvement measures.

Additionally, to support repairs for products under its ‘Eyeclon’ brand, MCNEX provides service parts and diagnostic programs. Instructions on how to request and use after-sales service (AS) are publicly available on the ‘Eyeclon’ website.

Quality Management System