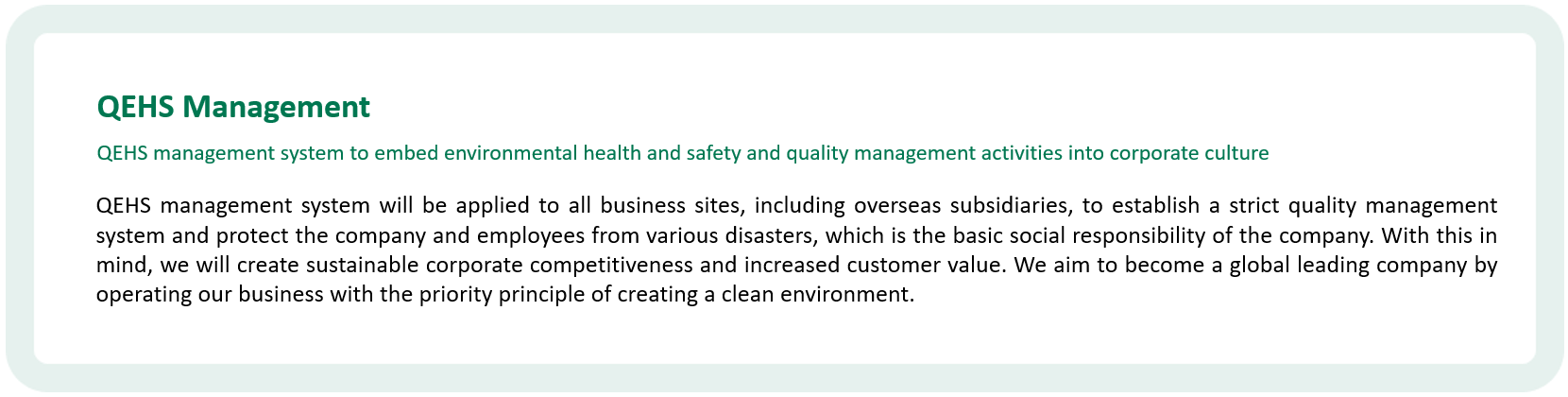

QEHS Management

MCNEX applies its QEHS management system across all its business sites, including overseas subsidiaries, to strictly manage environmental, safety and health, and quality aspects. Looking ahead, MCNEX aims to advance as a global leading company by protecting its employees from various risks through an integrated operating system and by making the creation of a safe and clean workplace environment its top priority.

QEHS Strategy

Safety and Health Management System

MCNEX operates a safety and health management system compliant with global standards, having initially obtained OHSAS 18001 certification and subsequently transitioned to ISO 45001. Its Incheon Songdo headquarters and Vietnam subsidiary undergo regular surveillance and recertification audits for the stable management and continuous improvement of their safety and health management system.

Additionally, MCNEX operates its ESG Hotline System, which can be used to report accidents, risks, and concerns related to safety and health. Internal and external stakeholders, including employees and partners, can use this hotline system to report safety incidents or concerns. Such reports are promptly processed according to established procedures. In 2024, there were zero reported cases concerning safety and health via this channel.

ISO 45001

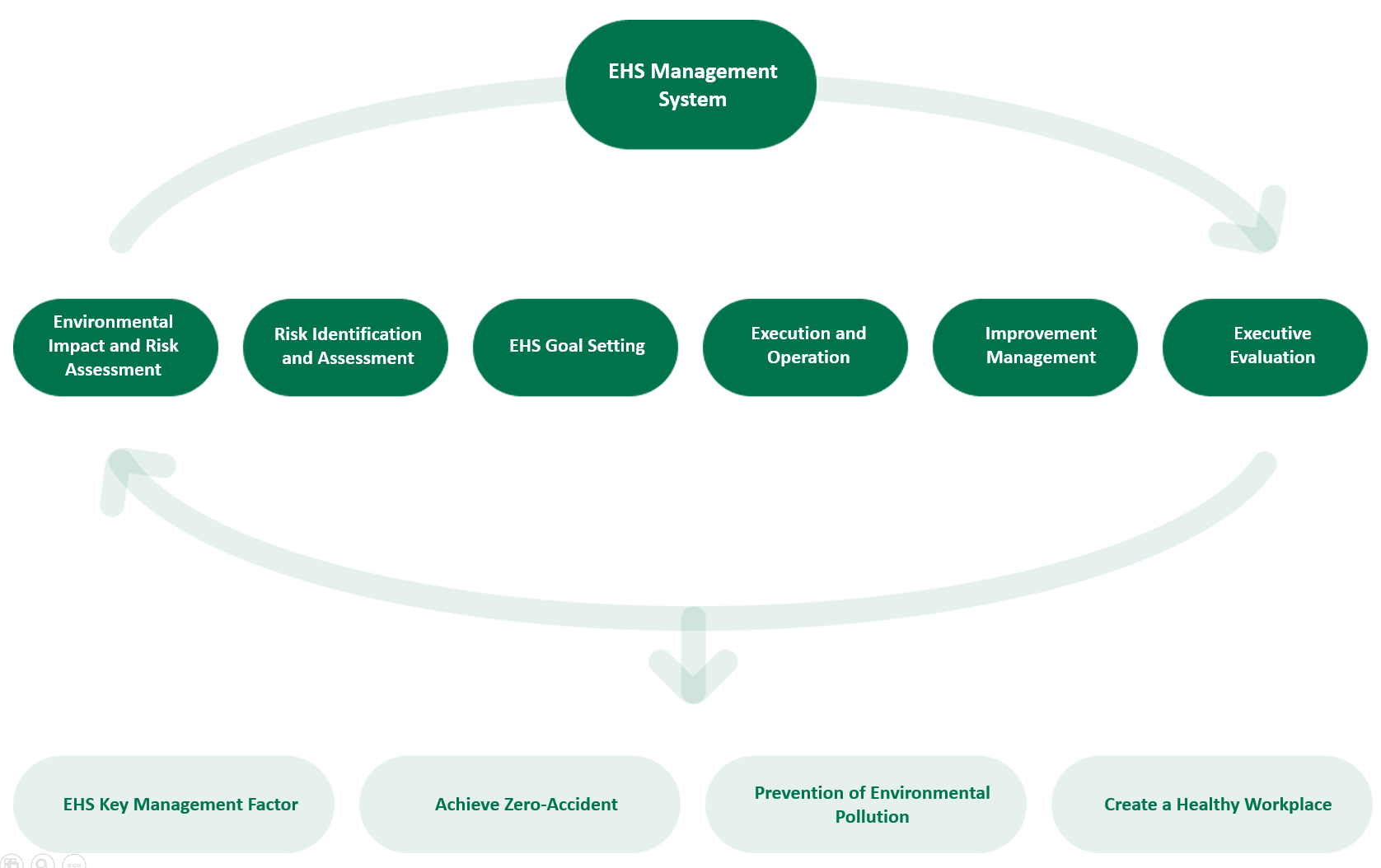

Safety and Health Organization

MCNEX has appointed the Head of its Management Support Division as its Chief Safety Officer (CSO), who oversees overall environment, safety, and health, and the company operates a dedicated occupational safety and health organization. The CSO plans and operates the integrated Environmental, Safety, and Health (ESH) management system, annually reviews operational performance, regulations, and legal compliance, and periodically reports these findings to the CEO. Furthermore, this dedicated organization ensures more professional and efficient work by appointing personnel specifically responsible for various safety and health tasks.

Additionally, MCNEX regularly deliberates and resolves important matters concerning safety and health through its Occupational Safety and Health Committee, composed of employee and company representatives. The Occupational Safety and Health Committee meets quarterly and supports employees in performing their duties within a safe working environment.

At the Occupational Safety and Health Committee meetings held in 2024, 100% of agenda items related to safety and health—such as ISO 45001 renewal, personal safety management, and personal hygiene management—were fully addressed and completed. Moreover, MCNEX operates an internal 'Safety and Health Feedback Channel' where employees can freely submit opinions on these topics. Through this channel, the company gathers information on safety and health incidents or errors and suggestions, and acts on them for improvement and ongoing management.

Organizational Chart

Safety and Health Risk Management

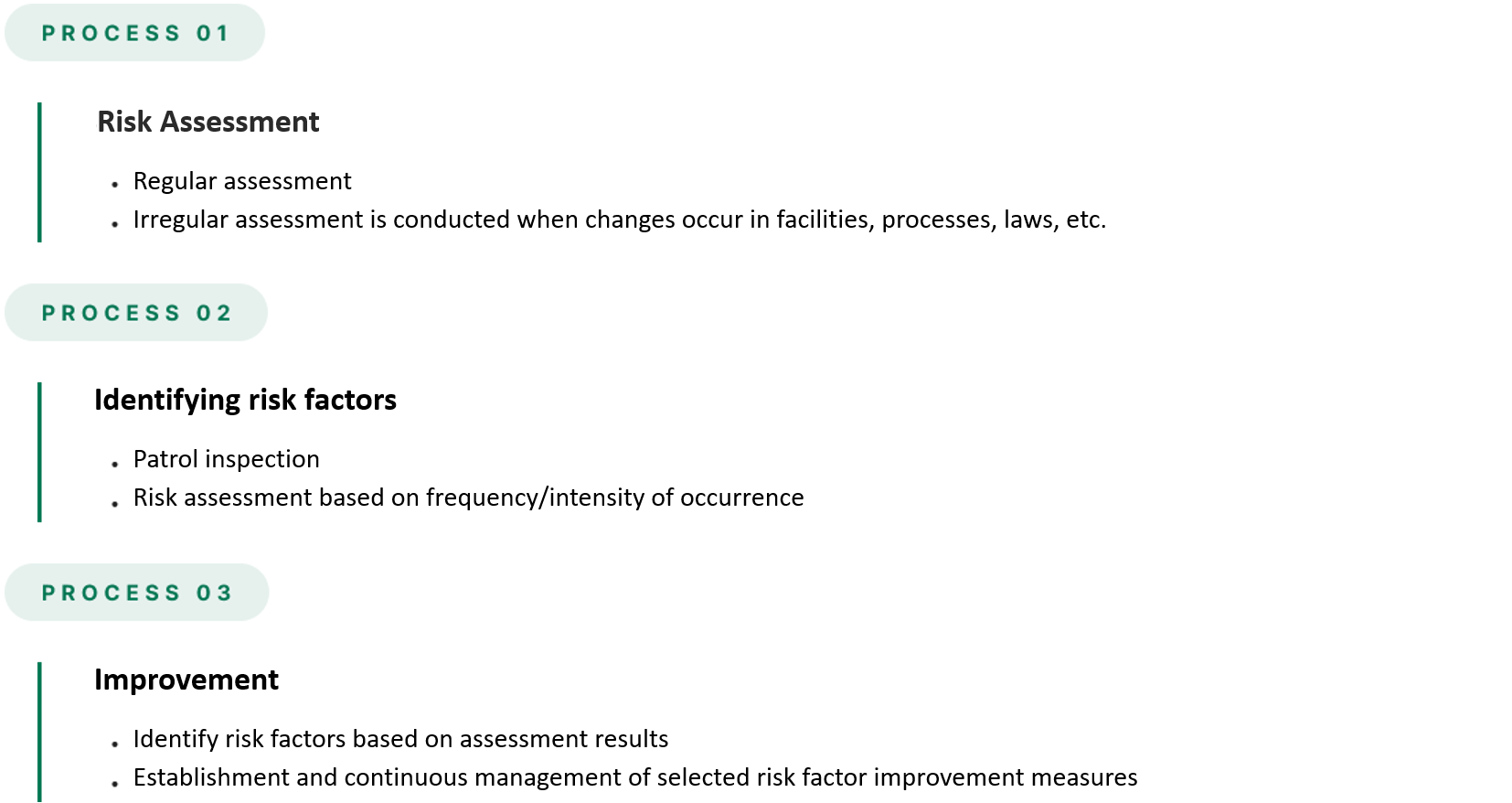

Safety and Health Risk Assessment

To proactively identify and mitigate risk factors within its business sites, MCNEX conducts risk assessments at all sites, including overseas subsidiaries. This risk assessment involves classifying risk factors into four categories and then, for each factor, calculating the frequency and severity of associated hazards to determine a risk level. Improvement activities are subsequently implemented based on this risk grading. Furthermore, these risk assessments mandate the participation of at least one employee per task or process, and a 100% completion rate is maintained through annual regular assessments. Through this approach, MCNEX strives to empower employees to actively engage in safety management activities and enhance their safety management capabilities. The risk assessment conducted in 2024 identified a total of 34 risks, all of which have been addressed with corrective actions.

Additionally, MCNEX VINA conducts its risk assessments following the labor and business ethics risk assessment process of the RBA (Responsible Business Alliance), a global initiative.

Risk Assessment Process

Management of Serious Accidents

MCNEX strives to prevent serious accidents that may occur at its business sites and to minimize any resulting damage. In the event of a serious accident, MCNEX promptly implements initial responses and first aid according to its established response process, and prepares an accident report. Through this, the company identifies the cause of the accident, formulates improvement measures, and carries out recurrence prevention activities. Through such safety management processes, MCNEX minimizes damage with immediate responses when accidents occur at its sites and prevents the recurrence of accidents from the same causes.

At MCNEX, there have been zero serious or fatal accidents in the past three years. There has been a total of one industrial accident (e.g., a fall), which represents a rate lower than the average accident rate in the same industry. For MCNEX VINA, there was one industrial accident in 2024, resulting in an LTIFR (Lost Time Injury Frequency Rate) of 0.1.

Safety Accident Prevention Activities

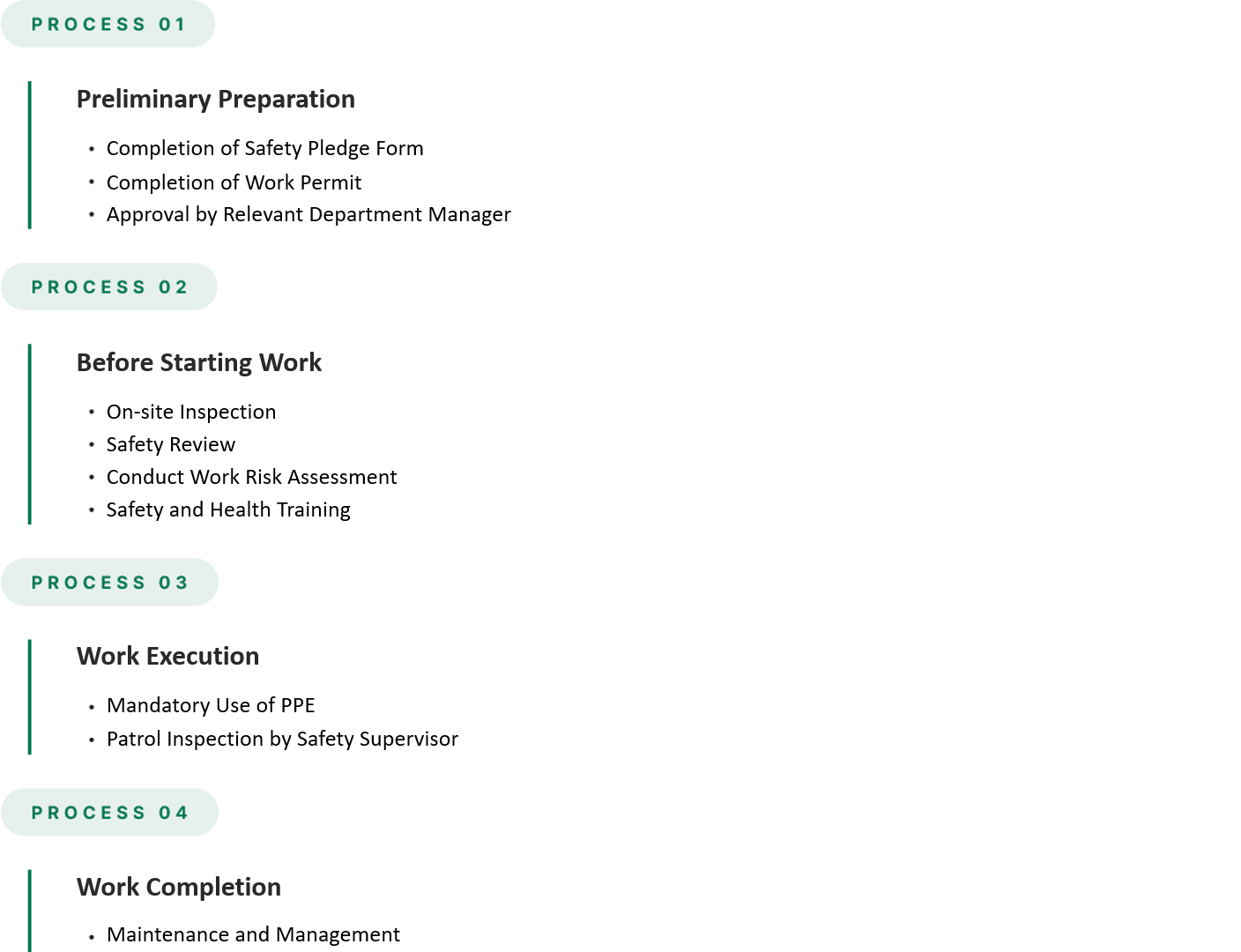

When tasks such as installation, maintenance, inspection, and cleaning involve risks, MCNEX prevents safety accidents by conducting a prior safety review to protect its employees before proceeding with the work. Before performing hazardous work, MCNEX mandates the completion of a safety pledge form and a work permit (or work notification form). The work is then carried out only after a safety review by the designated safety supervisor. Additionally, MCNEX provides workers with safety protective equipment (PPE) and devices, such as safety shoes, back support belts, and anti-electric shock devices, and conducts regular safety training. All hazardous tasks, including non-routine and high-risk operations, are performed under the supervision of a safety supervisor. Immediate action is taken if any violation of safety rules is observed during work.

Furthermore, to prevent safety risks at its business sites, MCNEX conducts annual equipment inspections. The headquarters conducts safety inspections for its pressure vessels and ensures these are periodically renewed. At MCNEX VINA, safety inspections are conducted for 193 pieces of on-site equipment, including compressed air tanks, oil separators, and compressed air pipes. These inspections are renewed periodically, thereby enhancing workplace safety and health.

Prior Safety Review Process

Accident Prevention Activities

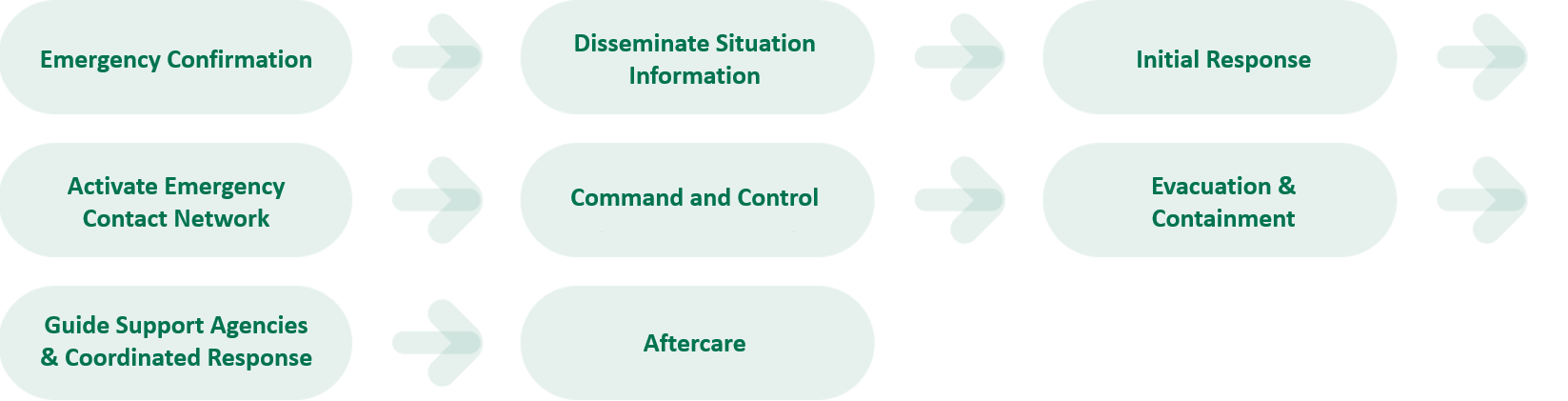

Accident Response System

MCNEX maintains a systematic management plan where emergency scenarios are categorized into four stages: Plan, Execute, Check, and Act (PDCA). Each stage is further defined by areas such as input, activity, output, and responsibility. In an emergency, all relevant departments are organized to form two squads and one team under the leadership of a Chairperson and Vice-Chairperson, enabling a swift and coordinated response.

Emergency Response Process

Emergency Response Training

To strengthen its accident response capabilities, MCNEX conducts regular annual training exercises based on various emergency scenarios. This emergency preparedness training assesses response capabilities using checklists tailored to specific scenarios, including earthquakes, typhoons, heavy rain, fires, infectious diseases, and cyberattacks. MCNEX records and archives the details of each training exercise. The company then identifies any issues or areas for improvement from these drills to implement enhancements.

Employee Safety and Health Training

MCNEX conducts safety and health training to enhance employees' awareness in these areas and to foster a strong safety culture. Additionally, MCNEX provides safety and health training to new hires upon recruitment and offers tailored, job-related training separately for office-based and non-office-based employees. This safety training extends not only to MCNEX's own employees but is also provided to the employees of on-site contractors, such as security and cafeteria staff.

Employee Health Management

To support the physical and mental well-being of its employees, MCNEX conducts annual general, special, and comprehensive health check-ups for all staff, as well as specific check-ups for employees traveling overseas, thereby aiming to prevent diseases. For employees identified with health concerns from these check-ups, MCNEX provides counseling and intensive follow-up management.

Additionally, to promote employee health and prevent/manage work-related illnesses and occupational diseases, MCNEX partners with local hospitals to provide medical services. In particular, it collaborates with local public health centers to operate smoking cessation clinics, emphasizing employee health management. To help employees quit smoking, MCNEX provides smoking cessation aids like vitamins and nicotine gum, periodically assesses their continued abstinence, and awards commemorative gifts for success. In 2023, 10 employees participated in the smoking cessation clinic, with 4 successfully quitting.

Beyond these, MCNEX supports in-house clubs for activities such as soccer, climbing, and golf, along with health promotion activities aimed at preventing cerebrovascular and cardiovascular diseases and metabolic syndrome. The company also provides rest areas, including lounges and sleeping rooms. Going forward, MCNEX will continuously strengthen its safety and health management capabilities to eliminate fundamental accidents by promoting employee health.